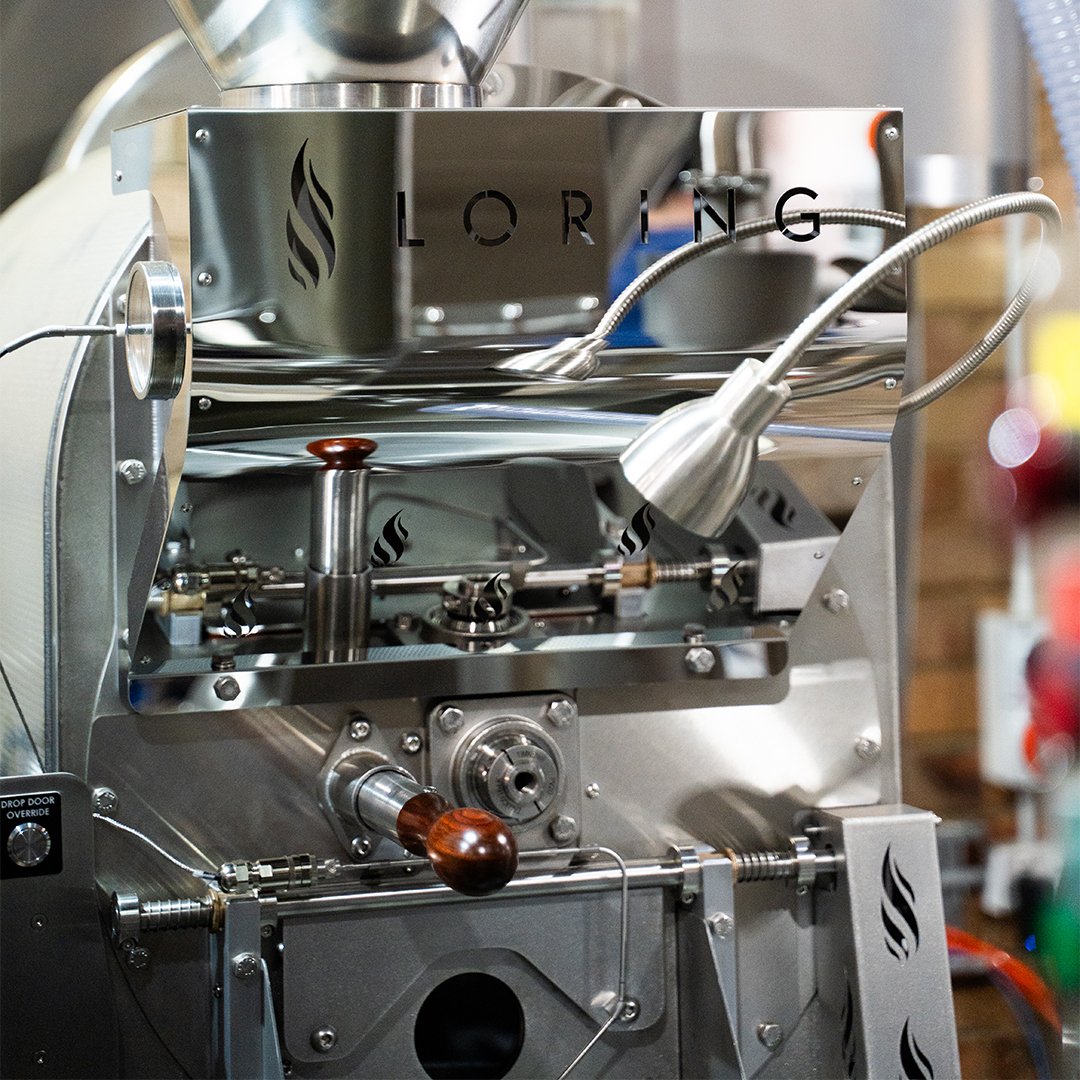

Phil here, Head of Coffee at Pablo & Rusty's and I'd like to introduce our newest team member and new coffee roaster, "Loring" aka The Falcon. We take a moment to reflect on all the good times we had with our old friend the “Probat”. Both are excellent roasters in their own right but have a few differences that are worth pointing out. But first let's have a quick look at the journey of replacing a coffee roaster.

Installation journey

Changing over roasting equipment is no easy feat. Led by our senior roaster and production manager we met weekly for 2 months leading up to the main event. Planning out where we would put it, when we would remove the old roaster and when we would move over to the new one. This and all the compliance details that came along with it meant we were pushing the limits with what we could do without impacting the operations of roasting. Carefully laid out plans, gas plumber’s consultations and meticulous forklift driving ensured that everything and everyone would be safe during the process. So after a few weeks of transition and intensive training along with profile matching and cupping we are in and finally roasting on the “Loring”!

Why the change-over?

First, we need to understand the main differences between roasters.

Main types of roasters

There are 2 main types of coffee roasters that are available and popular among roasteries. Drum roasters and air roasters or fluid bed roasters.

Drum roasters (the Probat) are the more common and traditional roasters used in the industry. These are essentially large drums made of thick cast iron or steel. These drums are generally directly heated by a flame underneath while the drum is rotated with paddles built into the drum to shuffle and mix the coffee while roasting to ensure a more even roast.

An air roaster (the Loring roaster) is generally a chamber where hot air is moved through to roast and mix the coffee around the same time to roast the coffee as evenly as possible (think a popcorn maker). This is done by heating air with a flame and pushing it through the chamber.

Now what is important about the way it roasts the coffee is the type of heat that is used.

There are 3 main types of heat

Convection - Convection heat is the movement of hot air through the chamber and mixing with the coffee transferring heat.

Conduction - Conduction heat is the transfer of energy through contact with a hot surface, in the case of the drum roaster it’s the temperature of and the material used in the drum of the roaster.

Radiation - Radiation is the transfer of heat through the energy waves radiating from the source flame or through the heat energy emitting from the surface of the drum itself.

Roasting coffee is understanding the source of heat transfer and being able to manipulate it in a way to create the roast profile that achieves the quality results you need to best express a coffee.

This brings us to our new friend “Loring”. Notably an “air” roaster, the Loring uses convection to transfer heat to the coffee while roasting it. It also uses a drum to hold the coffee but rotating paddles to move and mix the coffee around applying the heat evenly. This is different to the traditional drum roasters in that the drum is never in direct contact with the heat source and the material of the drum doesn’t allow for any significant heat transfer via conduction or radiation.

Advantages of Loring

The are many advantages to using a Loring these include;

Environmental sustainability - Due to their reduced energy consumption and smoke elimination features, Loring roasters are considered environmentally friendly options for coffee roasting operations. They align well with our sustainability goals and are considered to be up to 80% more efficient than a comparable drum roaster.

Consistent roasting quality - Loring roasters offer more precise control over roasting profiles, resulting in consistent and repeatable batches of coffee. This control is facilitated by their efficient heating system and airflow management, which help maintain stable temperatures and even roast development.

User-friendly design - Loring roasters are designed with the user in mind, featuring intuitive controls and automation options that streamline the roasting process. This can lead to increased quality and consistency in the output of roasted coffee.

Data logging - Loring roasters feature advanced data logging and automation, enabling real-time monitoring and adjustment of roast profiles via intuitive digital interfaces. This ensures precise control over temperature, airflow and roast duration, ensuring consistent quality across batches.

Conclusion

Change can bring a breath of fresh air (pun intended). This new roaster allows us to fine-tune the profile and batch sizes of our microlot coffees with greater precision. This means we can match the profile and quality of our Probat roasts while giving us room to develop the profiles further. Not only do we get the benefits of maintaining the quality we all know and love but we can align further with our sustainability goals through energy efficiency. We love our new team member and we know you’ll love the work it does too!